| Contact TEL:0282-86-0276 FAX:0282-86-0365 |

= SUB MENU =

| Laminated sheet metal

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Machine processing → To sheet metal!

Solid form! High accuracy with a low cost! |

||||||||||||||||||||||||||||||||||||||||||||||||||||

| 【Product layer sheet metal processing】 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| The product layer sheet metal processing of our company has materialized the following merit, by accumulating the metal plate that was processed and was press in place of cutting machine processing! | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

We suggest laminated sheet metal that

creation of the solid form with pile of sheet. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

| 【the Laminated product】 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Zeneba

Possibility that produce the system part simply |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Paper guide

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Stainless steel 4 sheets

Circle hole/Reamer processing |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

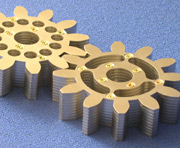

Gear

Production possibility even a big form |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

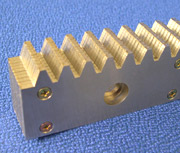

Rack

Long Shaku of a large module(3m) |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Automatic gate part

Aluminum and stainless steel 4sheets Position accuracy0.025 flatness0.05(The entire surface) |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Industrial devices part

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| 【The product layer metallic mold】 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changing to the metallic mold of machine cutting processing I propose the product layer metallic mold. Depending on a simple practical use metallic mold the low cost short time for delivery is materialized! It is many achievements of bending processing metallic mold and, diaphragm processing metallic molds. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| 【Product layer method】 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product layer method is decided by the usage and use environment, accuracy, demand strength of the product. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Besides please consult it because there is a development case,

although I am not able to announce here! |

||||||||||||||||||||||||||||||||||||||||||||||||||||