Strength

Services provided by ARKTECH., Co Ltd

Since our establishment in 1963, we have been striving to provide our customers with high quality products as a precision sheet metal company for many years.

We have been able to accumulate a high level of technology and know-how from our extensive experience.

Currently, we are also focusing on passing on the technology and developing human resources who will be responsible for the industry in the future. With our flexible manufacturing methods and well-developed quality control system, we will continue to help our customers give shape to their needs.

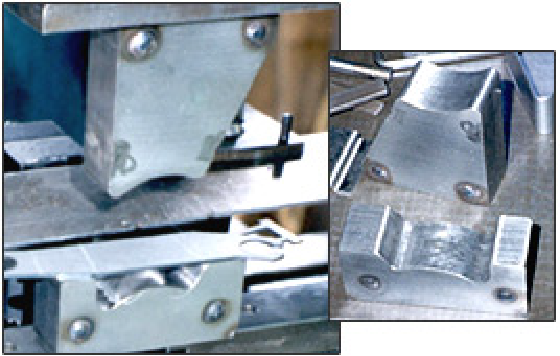

Our laminated sheet metal processing is a technology that creates three-dimensional shapes by stacking pressed metal sheets.

We have a wealth of experience in bending and drawing dies, and have achieved high strength, low cost, and quick delivery with practical, simple molds.

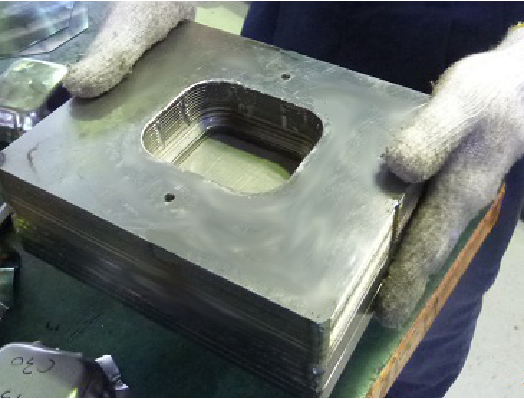

Laminated molds, which are made by stacking laser-processed metal sheets instead of conventional machining (machining, electrical discharge), have many features.

Advantages of using laminated sheet metal processing technology

- High productivity

- Quick delivery

- Cost reduction

- Maintaining accuracy

- High strength

- Special shape

- Hollow structure

- Vibration control

- Addition of advanced functions

-

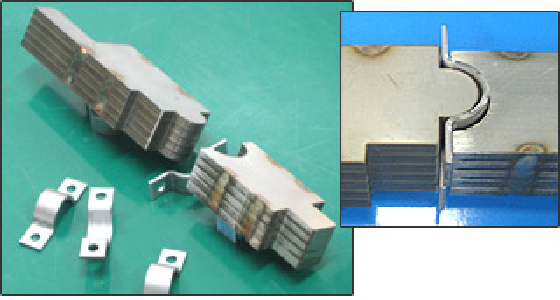

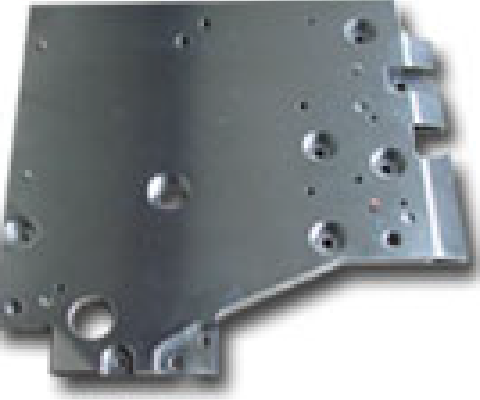

SUS laminated 4 pcs

Round holes are reamed after lamination

-

Laminated paper guide

Machining with four laminated SUS sheets → Sheet metal processing

-

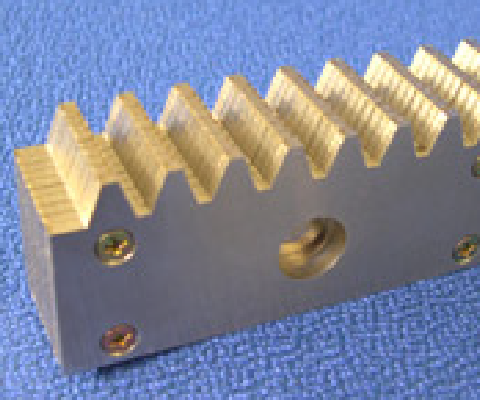

Laminated rack

Large module long (3m) is also possible

-

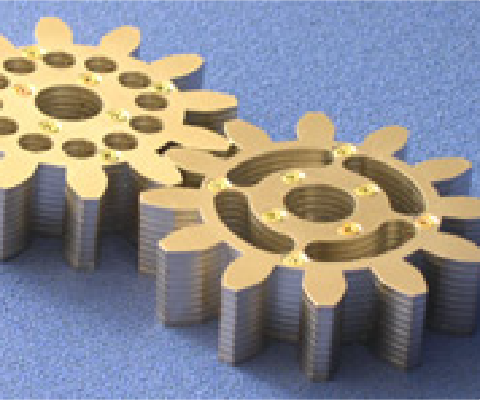

Laminated gear

Large shapes can also be manufactured

-

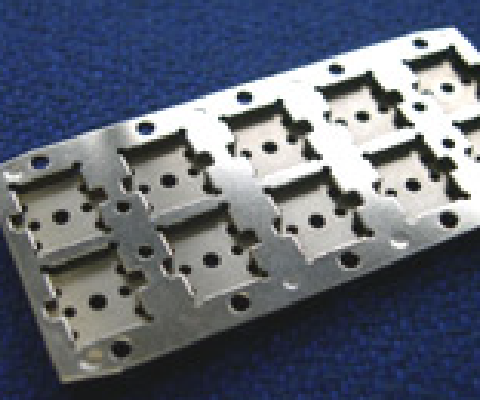

Chip carrier

-

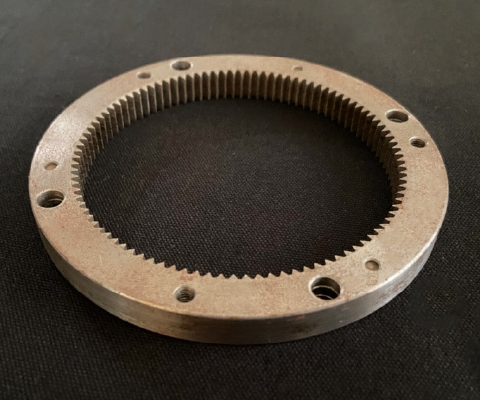

Laminated products(internal gear)

-

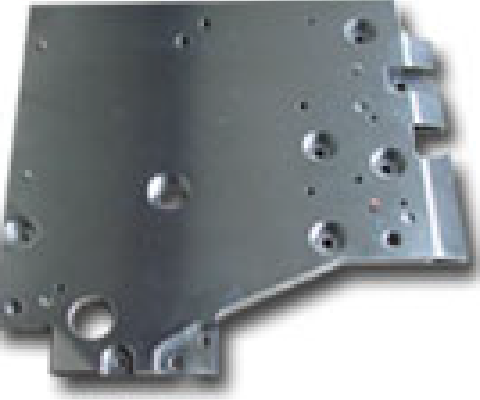

Automatic ticket checker parts

Laminated AI and SUS 4pcs

Positional accuracy 0.025/Flatness0.05(all surfaces) -

Geneva

Mechanism parts can be easily manufactured.

| The method of lamination is determined by the product's application, operating environment, accuracy, and required strength. | |

| Screw fixing | By attaching other parts, the relative tightening force can be secured. |

| Caulking | Rivets (blind rivets, etc.) Caulking pins (cutting pins for high precision) Embedded caulking (effective when the number of layers is small) |

| Bonding | When board adhesion is required or when strength is needed. Epoxy (high precision) Elastic adhesive (vibration absorption) Anaerobic adhesives Light curingLight curing Adhesive seal It is possible to laminate different materials as well as screwing and caulking |

| Welding | YAG-welding and Tig-welding. |

| Diffusion Bonding | Bonding by heat and pressure |

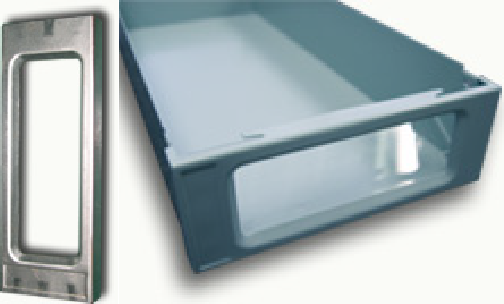

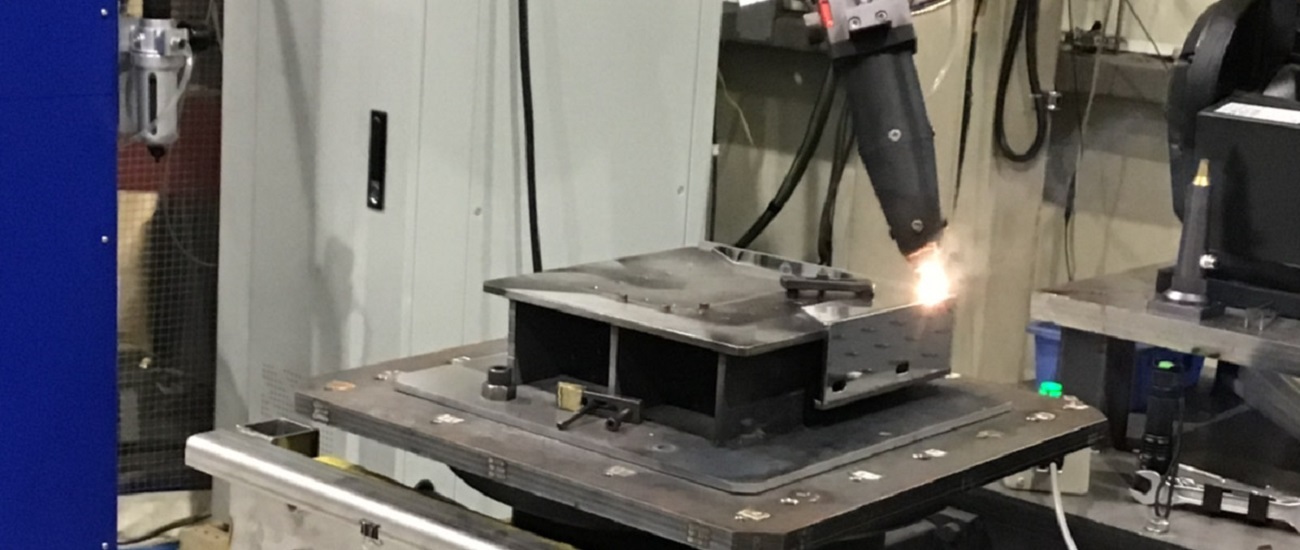

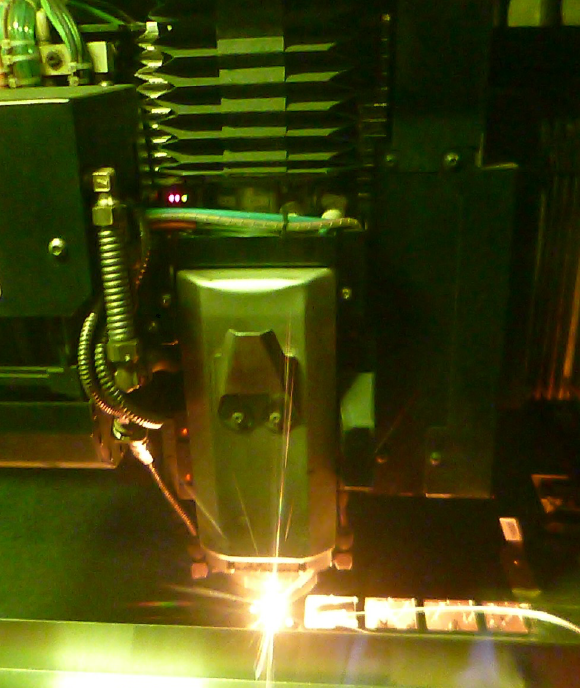

Our high-performance welding equipment realizes superior welding performance and is applicable to thick materials and aluminum materials that have been difficult to weld in the past.

Advantages of Fiber Laser Welding

- Fast solidification of material

- Persistence of melting state

- Good metallurgical structure in the weld zone

【Realization of an elegant appearance】

【Improved durability of thick welds】

【such as titanium and copper】

- Realization of high quality without quenching and finishing

- Reduction of distortion by high-density light

- Shortening of lead time by CW mode

- Enables thin plate and fine welding

- Reduction of running cost by improved oscillation efficiency

- No butt joint and high water resistance

-

Medical equipment

-

Food machinery

-

Semiconductor manufacturing equipment

-

Environmental field

-

Physical and chemical equipment

-

Manufacturing automation equipment

Our production system also allows us to respond flexibly to our customers' needs. We can provide systematic proposals from design and prototyping to mass production.

-

-

Quality Control

In November 1997, we obtained ISO 9001 certification, the international standard for quality systems.

We are the first company in the precision sheet metal industry to obtain ISO9001 certification in Japan, and it is extremely rare for small and medium-sized companies to obtain this certification in Japan.

As a sheet metal processing company that manufactures to order, we have been building a quality assurance system from the early stage and promoting standardization in order to reliably meet the diverse demands of our customers.

We believe that "people are treasure and valuable assets. Based on the idea that "human resources are human assets," we place the highest priority on human resource development.

We are actively involved in acquiring technical qualifications and skill tests to improve quality, and we have a support system in place for acquiring qualifications.